Why Digital Twins Are Taking Over Real-World Systems

- Technology

- October 31, 2025

- 327

Not long ago, the idea of having a virtual replica of a physical system sounded like a high-concept experiment—useful for simulations, maybe, but not much more. Fast forward to today, and digital twins are playing a central role in how airports, factories, utilities, and cities operate.

These real-time, data-driven models are no longer limited to engineering labs. They are becoming tools for decision-making, risk analysis, and operational efficiency in critical infrastructure. Here’s what’s making digital twins so useful—and why more industries are rushing to adopt them.

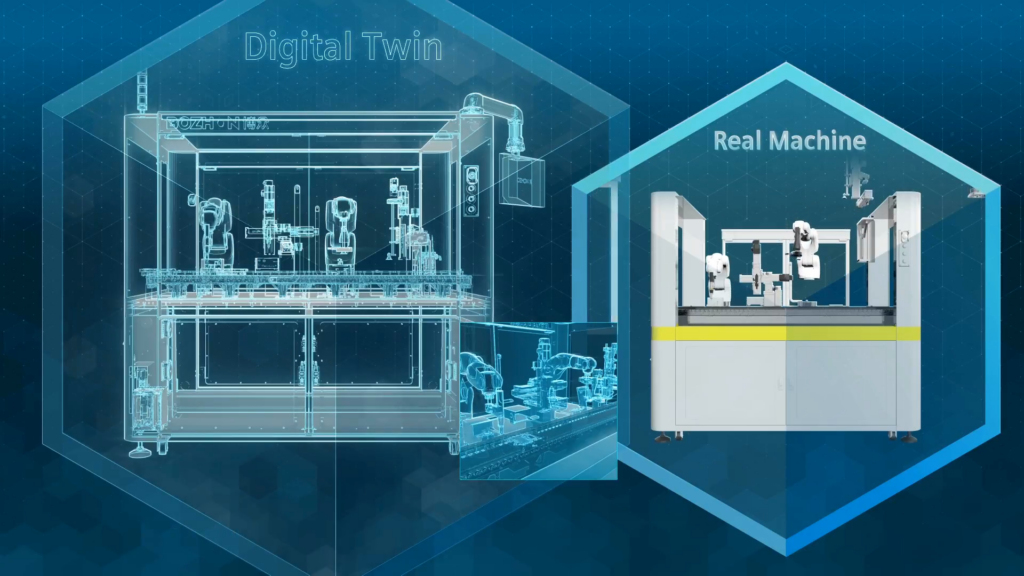

What Is a Digital Twin, Exactly?

A digital twin is a virtual model of a physical object, system, or environment. Unlike a static 3D model, a digital twin is connected to real-world data—often in real time.

That means if something changes in the physical world, the digital twin reflects it. Sensors feed data into the model, which helps track performance, predict problems, and simulate outcomes before changes are made. Digital twins are most powerful when they’re part of a live feedback loop: observe, analyze, adjust, repeat.

Airports, Airlines, and Predictive Planning

Airports were among the early adopters of digital twin technology. Major hubs now use these systems to simulate foot traffic, test emergency response times, or optimize gate assignments.

For example, an airport can run simulations on how new security checkpoint layouts will affect wait times—before changing anything in real life. Airlines also use digital twins to track aircraft components and predict maintenance needs, reducing downtime and improving safety.

Energy and Utilities: Monitoring What You Can’t See

In energy networks, digital twins are making invisible infrastructure visible. Grids are complex, and small failures can cascade into major blackouts. By creating virtual replicas of substations, transmission lines, and even whole networks, utilities can monitor equipment health, plan load balancing, and test upgrade plans in advance.

They also play a growing role in renewable energy. A wind turbine’s digital twin, for instance, can help operators monitor stress on blades, estimate lifespan, and schedule proactive repairs—all based on live sensor data.

Manufacturing: Smarter Than Smart Factories

Digital twins take Industry 4.0 to another level. In factories, they help model entire production lines—from robot arms to conveyor belts—and allow teams to optimize flow, improve uptime, or test new layouts without disrupting operations.

One of the biggest benefits in manufacturing is time savings. If a part or process fails, the twin can help diagnose the problem more quickly. If a new product is being developed, simulations on the twin can show whether the existing production setup can handle it—or what changes are needed.

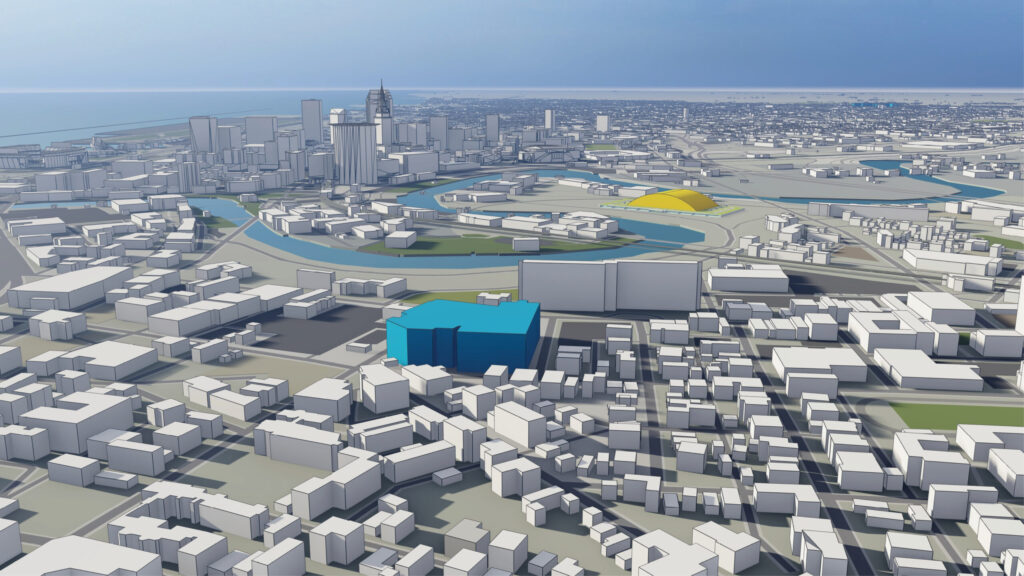

Cities and Infrastructure: Planning Without Guesswork

City planners are using digital twins to test public transport strategies, traffic systems, and even climate adaptation projects. With connected data from IoT sensors, smart cameras, and simulation engines, cities can predict how changes in population, weather, or zoning could affect how people move and live.

For example, adding a bike lane or changing a bus route can be modeled in the digital twin—forecasting real-world impact before anything is built.

Why It’s Catching On Now

Digital twin adoption is growing because a few key technologies have finally matured:

- Cloud computing makes large-scale simulations faster and cheaper

- Sensors and IoT devices provide better, real-time data

- Visualization tools make complex systems easier to understand

- Integration with AI makes predictions more accurate and useful

Together, these advances have made digital twins practical for businesses, not just researchers. They help cut costs, reduce downtime, and manage risk in systems too complex to manage by hand.

What Comes Next

As digital twins become easier to deploy, they’re likely to appear in more parts of daily life—logistics, retail, agriculture, and more. Eventually, they may be linked together in networks of twins, each representing a component of a larger system.

That’s when things get really interesting: instead of optimizing one machine or one building, we could optimize entire ecosystems—virtually, in real time. And at that point, the line between “model” and “reality” might start to blur.