Materials Become Smart: Software in the Physical World

- Technology

- December 30, 2025

- 226

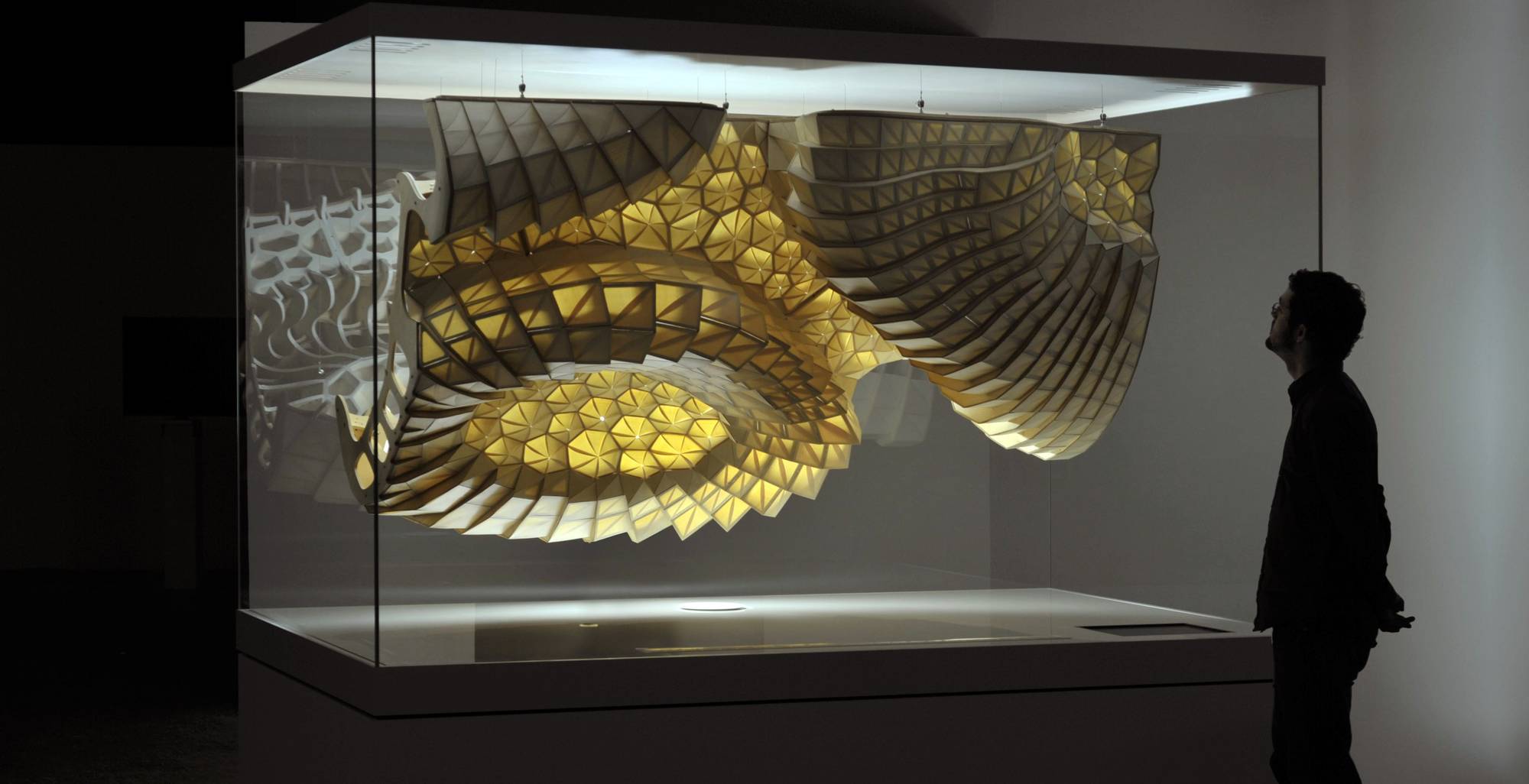

For decades, software lived on screens while materials stayed stubbornly physical. That line is starting to blur. A growing class of programmable materials and smart surfaces can now change their properties in response to code, sensors, or data—adjusting how they look, move, or behave in the real world. This shift is moving software out of devices and into buildings, machines, and everyday environments.

What Programmable Materials Actually Are

Programmable materials are physical substances whose properties can be altered in controlled ways. Instead of being fixed, they respond to inputs such as electricity, light, temperature, or magnetic fields. Software doesn’t just control them indirectly; it becomes part of how the material functions.

Smart surfaces are a close relative. These are panels, coatings, or structures that can sense conditions and react—changing opacity, shape, texture, or behavior based on data. In practice, many real-world systems combine both ideas.

Buildings That Adapt in Real Time

One of the most visible applications is in architecture. Electrochromic glass, used by companies like View, allows windows to automatically tint based on sunlight, time of day, or energy needs. Instead of blinds or manual controls, software adjusts how much light and heat pass through a building.

This isn’t a concept project. These systems are already installed in offices, airports, and commercial buildings. The benefit is not just comfort, but energy efficiency—reducing cooling loads without changing the structure itself.

Shape-Changing Materials in Engineering

Shape-memory alloys and polymers can be programmed to change form when triggered by heat or electricity. These materials are used in aerospace components, industrial actuators, and compact mechanical systems where traditional motors would be bulky or inefficient.

Because the “movement” is built into the material, software can activate transformations with minimal hardware. Engineers use this to create components that fold, deploy, or reconfigure themselves in tight spaces.

Smart Surfaces in Factories and Warehouses

In manufacturing and logistics, smart surfaces are being used to guide, sort, or interact with objects. Conveyor systems, adaptive grips, and responsive work surfaces can change friction, orientation, or flow based on what’s moving across them.

These systems rely on software models that interpret sensor data and adjust physical behavior on the fly. Instead of rigid production lines, factories gain flexible environments that adapt to different products without major retooling.

Reconfigurable Surfaces in Connectivity and Infrastructure

Programmable surfaces are also appearing in telecommunications. Reconfigurable intelligent surfaces—engineered panels that control how radio waves reflect or propagate—are being tested to improve wireless coverage in complex environments.

Rather than increasing transmission power, software adjusts how signals bounce through a space. This approach is being explored in dense urban areas, large venues, and industrial sites where traditional signal planning struggles.

Why This Shift is Happening Now

Several trends are converging. Sensors have become cheap and reliable, while control software is more precise. Simulation tools allow engineers to model material behavior before deployment. And energy-efficient actuation methods make it practical to scale these systems.

Just as importantly, industries are looking for ways to add flexibility without rebuilding entire systems. Programmable materials let companies change behavior through updates, not physical replacements.

Limits and Open Questions

Despite the progress, programmable materials are not magic. Many systems still have limited lifespans, higher upfront costs, or narrow use cases. Maintenance and reliability remain critical concerns, especially in infrastructure and industrial settings.

There’s also a skills gap. Designing systems where software and materials are tightly linked requires collaboration between disciplines that don’t always overlap—materials science, mechanical engineering, and software development.

Software’s Next Surface

Programmable materials and smart surfaces mark a shift in how technology shows up in the world. Instead of adding more screens or devices, software becomes embedded in the environment itself.

The result is a physical world that can adapt, respond, and evolve—sometimes invisibly. As these systems mature, the most interesting question won’t be what they look like, but how often we interact with software without realizing it’s there at all.